Fast, Safe & Efficient Charging

PULSECHARGE

Pulse Charge is redefining the boundaries of battery charging. Our patented high-voltage pulsed charging system enables ultra-fast charging – up to 10× faster — with zero thermal risk or degradation.

Compatible with existing lithium-ion chemistries, we eliminate the need for special batteries, cooling systems, or infrastructure redesign.

The result: safer, smarter, universally integrable fast charging. From consumer tools to energy storage.

Our mission is to develop and manufacture devices for ultra-fast charging of lithium-ion batteries.

Reinventing Fast Charging

Ultra-fast, low-current pulse technology charges lithium-ion batteries in minutes with minimal heat

CHARGING LITHIUM-ION BATTERIES IN MINUTES — SAFELY, UNIVERSALLY, SCALABLE

Pulse Charge is redefining the boundaries of battery charging. Our patented high-voltage pulsed charging system enables ultra-fast charging – up to 10× faster — with zero thermal risk or degradation.

Compatible with existing lithium-ion chemistries, we eliminate the need for special batteries, cooling systems, or infrastructure redesign.

The result: safer, smarter, universally integrable fast charging. From consumer tools to energy storage

Upcoming 3D Animation Video

On the next slide, you will see a full-screen 3D animation that demonstrates our charging process in action.

The video schematically illustrates:

•Battery charging dynamics

•Cathode ionization process

•Ambipolar diffusion

This animation provides a clear and intuitive visualization of the technology behind PulseCharge.

Overview of our Technology Charging Overview:

Ultra-fast charging at low current

During each pulse, a charging current flows through the battery under a voltage that significantly exceeds the nominal cell voltage (3.7 V for lithium-ion batteries).

Due to the small interelectrode distance (approximately 10–30 μm), the resulting electric field strength in the interelectrode space reaches levels sufficient to ionize the cathode material of the battery.

The generated lithium cations and electrons then diffuse from the cathode to the anode during the pause between pulses, driven by the concentration gradient of free charge carriers. This process results in additional battery charging and follows the mechanism of ambipolar diffusion.

Thus, part of the battery’s charge is delivered directly by the external current during the pulse, while another part is contributed by internal diffusion processes during the pause.

The higher the applied voltage and the shorter the pulse duration, the greater the contribution of the diffusion-driven component—which does not lead to heating of the battery.

Partners & MISSION

OUR MISSION

Makich Danielyan

Pavel Maslyakov

-

Ultra-fast charging at low current

-

Revolutionizing battery charging technology with high-speed, low-heat solutions that extend battery life.

-

Research on lithium-ion battery charging methods and the phenomenon of ambipolar diffusion during charging was carried out over four years in Moscow, in our own laboratory, funded by personal resources.

-

Previously, we developed and successfully implemented a method for desulfation of sealed lead-acid batteries using high-frequency pulses.

Igor Peer

CC/CV vs PulseCharge:

A New Approach to Battery Charging

80%

20%

In the standard CCCV method, a battery charges relatively quickly only up to 80%, after which the speed drops sharply. Attempts to accelerate this process by increasing current lead to overheating and battery degradation.

100%

PulseCharge – uses very short high-voltage pulses with low current, separated by longer pauses. This method enables superfast safe charging all the way to 100%, while minimizing heat and extending battery life.

All existing charging methods on the market require delivering to the battery an amount of electric charge equal to its nominal capacity — whether in constant current (CC) mode or in conventional pulse-periodic modes.

Therefore, for ultra-fast charging in ~15 minutes, the current must reach ~4C (C = nominal capacity). This inevitably causes significant heating of the battery (necessitating complex cooling systems). Moreover, at 4C, the cell can only be charged up to ~80% of its capacity. Beyond that point, current must be reduced, which extends total charging time. For example, Tesla’s supercharging requires ~25 minutes to reach 80% state of charge.

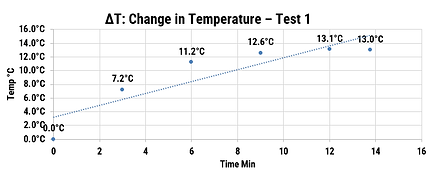

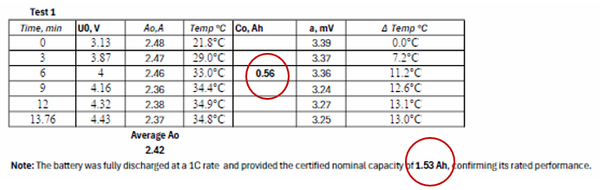

In our experiment (Section 1), the cell was charged with a current of 2.44 A and exhibited only a 12 °C temperature rise. Using any other charging method currently available, the required current would be ~6.7 A. Such high current not only increases energy losses and cooling demand but, most critically, leads to loss of nominal capacity and even potential cell destruction.

With our method, approximately 63.3% of the charge is delivered through internal diffusion, while only 36.7% comes directly from the external source. As a result, the battery heats only minimally (since internal diffusion does not constitute electric current and therefore does not contribute to heating). The nominal capacity is preserved. In fast charge–discharge tests at 1C, capacity fade was measured at just 2.8% after 350 cycles. For comparison, Samsung specifies ~23% capacity fade after only 250 cycles under the same conditions.

It is important to emphasize that in this process, the law of conservation of energy is not violated.

It is also important to note that our method charges the battery from 0% to 100% state of charge. Laboratory studies further demonstrated that by increasing the overvoltage above the nominal value, the proportion of charge gained via internal diffusion increases.

At present, our pulse-periodic high-voltage method is the only approach that achieves ultra-fast charging without capacity loss or structural damage — and it opens the path to charging an EV battery in just five minutes, equivalent to conventional refueling time.

All existing methods of charging lithium-ion batteries, whether by pulsed or constant current, require transferring the entire charge from the source to the battery.

Our charging method is a hybrid: part comes from the current source, and part is provided by ambipolar diffusion.

This is exactly what makes our method different from all the others.

System Description: Pulse Charge Prototype – 100W Lab Setup

• The charging system continuously maintains a constant voltage across a bank of buffer capacitors, which are connected to the battery via an electronic switch.

When the switch is closed, the battery receives a controlled portion of electrical energy from the buffer capacitors over a defined time interval.

Afterward, the battery is disconnected from the capacitors, and following a pause, the cycle repeats.

• The operation of the electronic switch is controlled by a signal generator that defines the pulse timing and frequency.

• The key parameters — constant voltage level, capacitance value of the buffer capacitors, pulse duration, and repetition rate — are selected based on the specific characteristics of the battery and the requirements of the technical specification.

PULSE CHARGE TESTING ON SAMSUNG 18650-15M Cells — 10-Cycle Analysis

Standard Charging Protocol — Samsung INR18650-15M (1.5Ah)

Nominal voltage: 3.6 V

Full charge voltage: 4.2 V

Recommended charge current: 0.75 A (0.5C)

Maximum charge current: 4.0 A

Standard charge time: ~2.5 hours (0.5C)

Fast charge time: ~1.2 hours (1C)

End-of-charge current (CV mode): ~100 mA

Charging method: CC/CV (Constant Current / Constant Voltage)

Charging temperature range: 0°C to 45°C

Experimental Objective

The purpose of this experiment was to evaluate ultra-fast charging behavior using our Pulse Charge technology on two Samsung INR18650-15M 1.5Ah batteries.

We conducted 10 charge–discharge cycles for each cell:

-

Ultra-fast charge using Pulse Charge

-

1-hour discharge

-

Repeated 10 times per cell

Measurements Collected:

-

Charging duration per cycle

-

Temperature rise during charge

-

Charge current profile

-

Deviation from standard protocol

VALIDATION EXPERIMENTS IN BAR ILAN LAB

SCIENTIFIC VALIDATION

Commercial 1.5Ah

cylindrical 18650 Li ion batteries

Conclusion:

This table presents one of the experimental results demonstrating the performance of our Pulse Charge system. Notably, during charging, only 0.56 Ah was directly delivered to the battery, while 1.53 Ah was extracted during discharge. This indicates that approximately 0.97 Ah was contributed through internal ambipolar diffusion processes, confirming the effectiveness of our technology beyond conventional current-based energy transfer.

SCIENTIFIC VALIDATION: PROF. DORON AURBACH

September On1, 2025, we received a detailed report from Prof. Doron Aurbach’s laboratory.

Validated at Bar-Ilan University

-

10 cycles Pulse Charge = 1.5 Ah full capacity

-

No degradation or heat damage

-

Ongoing: 1000+ cycles

PulseCharge fast charge time: ~0.25 hour !

Pulse Charge deserves green light to continue R&D – Prof. Aurbach

Degradation After 250 Ultra-Fast Charging Cycles

Internal Laboratory Endurance Testing

This slide presents the results of charge–discharge cycles performed in our own laboratory.

Using Pulse Charge Tech technology, the Samsung INR18650-15M battery retained its capacity with less than 2% loss after 250 ultra-fast charge/discharge cycles (13.5 min charge / 1.5A( 1C) discharge), with no noticeable degradation or performance drop.

After 250 cycles at 1C/1C, the Samsung INR18650-15M can be expected to lose approximately 23% (!) of its capacity by Samsung battery protocol.